Asset Optimization Services (AOS) is committed to enhancing energy efficiency and building system reliability across campus. Through data-driven solutions and strategic improvements, AOS strengthens infrastructure resilience while reducing costs and energy usage. These efforts ensure high-performing building systems that support the university’s commitment to excellence in design, construction, and a sustainable future.

Explore our operational successes below and see how AOS is making an impact.

58.6 %

reduction in steam, chilled water, and electricity costs in a two-year comparison at Visual Arts Building.

What is Total Cost of Ownership?

Total cost of ownership (TCO) is a way of looking at the bigger picture when it comes to asset management at the university. TCO determines total cost of an asset—like a facility or a piece of equipment—throughout its entire lifecycle, from initial purchase cost, to operation and maintenance costs, utility cost to run the asset, and to the eventual end of useful life and removal. Even if the initial purchase cost is higher, an asset with a lower TCO may be a better value in the long run.

Heat Recovery Chiller Investigation

Core service: Total Cost of Ownership Resource

AOS investigated Heat Recovery Chillers on campus to determine that the equipment was performing as intended to reduce energy use and costs. Heat Recovery Chillers are a type of HVAC system that allow heating and cooling at the same time, utilizing heat generating during the cooling process for heating.

AOS launched an investigation to determine whether these systems were truly delivering energy and cost savings as expected. The goal was to assess their total cost of ownership and decide whether to integrate them into future projects.

A collaborative team worked to restore the system to full functionality, using real time building control data to analyze energy consumption and costs, addressing each issue methodically until all inefficiencies were resolved.

As a result, the equipment is now operating as intended, with initial data showing reduced steam and chilled water usage. Ongoing monitoring will ensure savings persist across all seasons, leveraging data to determine the Total Cost of Ownership for the equipment.

PBDB High Quality Water Investigation

Core Service: Building Performance Optimization

AOS investigated an issue with premature failures of Reverse Osmosis (RO) membranes in the Pappajohn Biomedical Discovery Building high-quality water system, initially suspected to be caused by undersized carbon filters. With a potential $85,000 cost for larger filters, a deeper analysis was conducted to pinpoint the root cause.

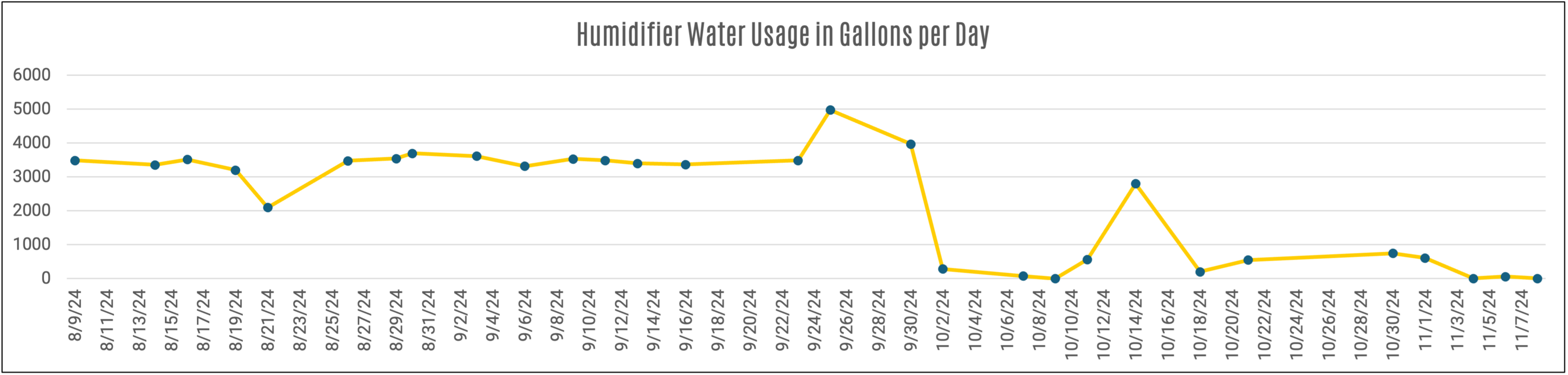

AOS examined the installed equipment and water usage, uncovering unexpected excess water consumption in building humidifiers. Identified issues included stuck-open drain coolers and incorrect control settings which were causing the humidifiers to drain more frequently than necessary. Correcting these issues led to a daily water savings of over 3,000 gallons.

Additionally, AOS identified a cross-connection between the deionized (DI) water system and the steam condensate system, diverting DI water into the steam condensate system when the DI pumps ran.

Further investigation by Engie determined that the existing RO membranes were not well-suited for the system and will replace them with more appropriate ones during the next maintenance cycle.

With these corrections in place, the need for an expensive carbon filter upgrade has been eliminated, optimizing system performance, reducing waste, and ensuring long-term efficiency.

UI Design Standards Successes

Core Service: UI Design Standards and Procedures Support

The University of Iowa continues its commitment to excellence in design and construction by refining its design standards to ensure efficiency, security, and long-term reliability.

Recent updates include narrowing approved Variable Frequency Drive (VFD) manufacturers to three, improving training consistency, streamlining maintenance, and ensuring readily available replacement parts. VFDs play a crucial role in optimizing motor speed, reducing energy consumption, and enhancing overall energy efficiency.

Additionally, the university has standardized the use of stainless-steel hydronic isolators due to their superior longevity and reduced risk of catastrophic failure. Stainless-steel hydronic isolators are a component of hydronic heating systems that allow for the isolation of specific parts of the system.

These strategic updates not only enhance system performance but also reinforce the university’s dedication to building a resilient infrastructure that supports the campus and community well into the future.

Completed Energy Fund Projects

Core Service: Energy fund project prioritization

The AOS team developed a scoring matrix that selects energy and reliability projects for funding from the utility rate energy fund. Since fiscal year 2024, over $1 million in projects have been approved in all areas of campus, from GEF buildings, University Housing and Dining, UIHC and Athletics. Fiscal year 2024 included a variety of campus improvements, ranging from updating to LED lights in Stuit Hall, to upgrading building controls in Mayflower Hall, and to updating the General Hospital steam pump. New projects are selected for funding each fiscal year—submit a project to enhance efficiency and reliability in your building!

$ 1.1 million

reinvested in energy and reliability projects since FY2024